BALON es uno de los principales fabricantes de válvulas industriales a nivel nacional U.S.A e internacional.

Aparecen en el Monograma API 6D de Septiembre/1996 (American Petroleum Institute), con un sello múltiple (patentando por BALON)

Cuentan con un sistema eficiente como la bola 100 % esférica; tienen un diseño único que permite un ensamble que brinda máxima seguridad, reduce el tiempo y elimina el riesgo de accidente en el manejo del producto.

Fabricado de acuerdo a las normas internacionales API, API6FA, API5B, API6D, API594; ANSI, B16.5, B16.10B, B16.34, B2.1; MSS, SP6, SP25, SP72, SP82, SP84; NACE, MR.01-75; entre otras.

-

Válbulas de Bola

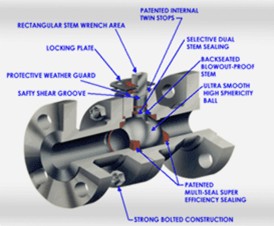

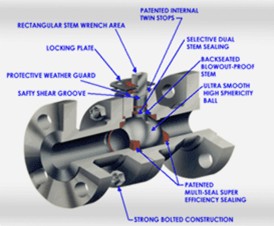

The Balon ball valve – Totally advanced

Balon has eliminated the need for grease fittings, lube channels, and regular lubrication, versus other designs.

Unique sealind approach

The Multi-Seal seat design has given impetus to the development of an overall valve which embodies several design improvements.

Backseated stem

Stems are backseated and therefore blowout proof. And they provide metal-to-metal backup sealing in the event of a fire. This secondary metal-to-metal sealing is also provided internally behind the seat area.

Simlified top works

Bolts and glands and complicated stem assemblies are totally absent in the Balon valve to assure a simpler, more trouble-free valve. Hazards associated with bolted stem retainers and packing adjustment screws or bolts have been eliminated. Even the stops are internal and give dual precise stopping support during opening or closing. The stem area is grease-packed and protected by a plastic weather guard to shield the vital area from external elements.

The Balon stem design eliminates troublesome bolting, adjustment screws, packing glands, and any need for field lubrication. The Result:

No problems associated with adjustable packing.

No danger of blowout caused by failure of retaining assembly.

No external attack by corrosion and foreign abrasives.

No nuisance of field lubrication and risk of leakage through grease channels.

Furthermore, the heavy duty wrench flats on the Balon Series F and Series S valve stems allow the operation of these valves with standard wrenches wherever space must be conserved, wherever accidental valve operation must be prevented, and wherever a wrench is more convenient.

Many manufacturers continue to apply complicated and outdated design solutions to old stem problems:

Valve stems are often retained by external bolts or screws, which can corrode or be vibrated loose, sometimes resulting in stem blowout.

Adjustable stem packing is frequently employed for stem sealing, despite its tendency to leak, its need for regular maintenance, and its consequent increase in valve operating torque.

Double O-Rings are sometimes incorporated, risking the entrapment of pressure between the O-Rings and often resulting in higher operating torque

Balon's philosophy envisions design improvement by simplification, not by complication. Balon's simple, functional stem design - a careful combination of interrelated improvements - represents a dramatic advance over conventional stem design. -

Válvulas de Chequeo

The Balon check valve-key benefits

- Unparalleled Design

- Uncompromised Quality

- Unequaled Safety

Openly challenging outdated concepts

After years of intensive, painstaking development and testing, Balon has breathed new life into the check valve art.

The Balon design, a total departure from the tired design of commonly available check valves, incorporates an innovative Disc and Seat Module. With this innovation, Balon has been able to eliminate hazardous screwed and bolted bonnets.

- No more blown bonnets.

- No more leaking bonnet connections.

- No more corroding and weakened bonnet joints.

Innovative, advanced and versatile

By utilizing this patented flow checking mechanism, Balon has been able to provide a wafer check valve which has no equal on the market. It offers fresh solutions to old problems. It greatly improves flow, enhances sealability, and makes maintenance simple, easy, and quick.

The seat

It's an integral part of the replaceable module and not cast into the body as in other check valves.

The disc

It has an integral pivot pin. No problem with wear prone pins and bushings. A positive solution to early mechanical failure.

The pivot bearing

It's part of the seat module and not the valve body. It is a replaceable part, allowing complete valve renewal.

Improvement over outdated designs

On conventional long and thin pattern valves, the disc is severely intrusive at its maximum open position. The Balon disc on the right allows for relatively unobstructed flow.

38% greater area

At right is shown the comparative bore diameter of a conventional two inch thin pattern check valve compared to Balon’s new design. Balon provides 38% more flow area in this size.

WAFER CHECK VALVES

(Thin & Long Pattern)

-

ANSI Class 150 (285 PSI WP)

Thin Pattern

Forged Steel Body Construction

Wafer Check Carbon Steel

- Thin Pattern Swing Check Valve

- ANSI Class 150 (285 PSI WP)

- 2" Through 6"

- Thin Pattern Swing Check Valve

-

ANSI Class 300 (740 PSI WP)

Thin Pattern

Forged Steel Body Construction

Wafer Check Carbon Steel

- Thin Pattern Swing Check Valve

- ANSI Class 300 (740 PSI WP)

- 2" Through 6"

- Thin Pattern Swing Check Valve

-

ANSI Class 600 (1480 PSI WP)

Thin Pattern

Forged Steel Body Construction

Wafer Check Carbon Steel

- Thin Pattern Swing Check Valve

- ANSI Class 600 (1480 PSI WP)

- 2" Through 6"

- Thin Pattern Swing Check Valve

-

ANSI Class 150 (285 PSI WP)

Long Pattern

Forged Steel Body Construction

Wafer Check Carbon Steel

- Long Pattern Swing Check Valve

- ANSI Class 150 (285 PSI WP)

- Long Pattern Swing Check Valve

-

ANSI Class 300 (740 PSI WP)

Long Pattern

Forged Steel Body Construction

Wafer Check Carbon Steel

- Long Pattern Swing Check Valve

- ANSI Class 300 (740 PSI WP)

- Long Pattern Swing Check Valve

-

ANSI Class 600 (1480 PSI WP)

Long Pattern

Forged Steel Body Construction

Wafer Check Carbon Steel

- Long Pattern Swing Check Valve

- ANSI Class 600 (1480 PSI WP)

- Long Pattern Swing Check Valve

SERIES D

Threaded End Connection

-

Series D Carbon Steel

Threaded End

Threaded Body Construction

Series D Carbon Steel

- Top Entry Swing Check Valve

- ANSI Class 150 (285 PSI WP)

- 1" Through 2"

- Top Entry Swing Check Valve

-

Series D Ductil Iron

Threaded End

Threaded Body Construction

Series D Ductile Iron

- Top Entry Swing Check Valve

- To 2000 PSI WP

- 1" Through 2"

- Top Entry Swing Check Valve

-

Series D Aluminium Bronze

Threaded End

Threaded Body Construction

Series D Aluminum Bronze

- Top Entry Swing Check Valve

- To 2000 PSI WP

- 1" Through 2"

- Top Entry Swing Check Valve

SERIES C

Threaded End Connection

-

Series C Ductile Iron 2000

Threaded End

Bolted Body Construction

Series C Ductile Iron

- Swing Check Valve

- 2000 PSI WP

- 2" Through 3"

- Swing Check Valve

-

Series C Ductile Iron 750

Threaded End

One Piece Body

Series C Ductile Iron

- Swing Check Valve

- 750 PSI WP

- 2" Through 3"

- Swing Check Valve

-

Series C Ductile Iron 1000

Threaded End

Threaded Body Construction

Series C Ductile Iron

- Swing Check Valve

- 1000 PSI WP

- 2" Through 3"

- Swing Check Valve

-

Series C Carbon Steel

Threaded End

Bolted Body Construction

Series C Carbon Steel

- Swing Check Valve

- 3000 PSI WP

- 2"

- Swing Check Valve

-

Series C Carbon Steel 3000

Threaded End

Threaded Body Construction

Series C Carbon Steel

- Swing Check Valve

- 3000 PSI WP

- 1" Through 2"

- Swing Check Valve

-

Series C Carbon Steel 1000

Grooved End

Threaded Body Construction

Series C Carbon Steel

- Swing Check Valve

- 1000 PSI WP

- 2" Through 3"

- Swing Check Valve

-

Series C Carbon Steel 150

Flanged End

Bolted Body Construction

Series C Carbon Steel

- Swing Check Valve

- ANSI Class 150 (285 PSI WP)

- 2" Through 6"

- Swing Check Valve

-

Series C Carbon Steel 300

Flanged End

Bolted Body Construction

Series C Carbon Steel

- Swing Check Valve

- ANSI Class 300 (740 PSI WP)

- 2" Through 6"

- Swing Check Valve

-

Series C Carbon Steel 600

Flanged End

Bolted Body Construction

Series C Carbon Steel

- Swing Check Valve

- ANSI Class 600 (1480 PSI WP)

- 2" Through 6"

- Swing Check Valve

-

Series C Aluminium Bronze

Threaded End

Bolted Body Construction

Series C Aluminum Bronze

- Swing Check Valve

- 3000 PSI WP

- 2"

- Swing Check Valve

-

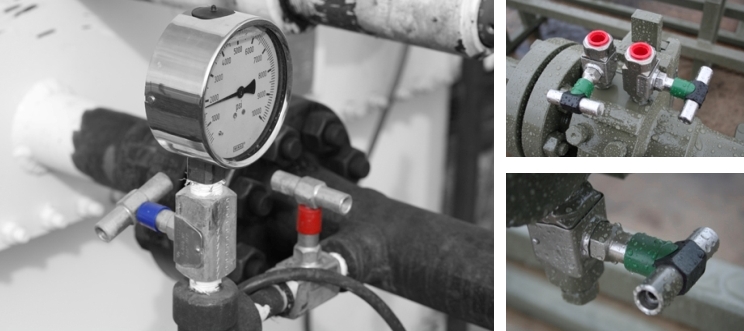

Válvulas de Aguja

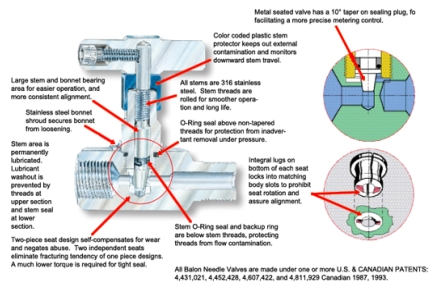

Four decades of valve research, design, and manufacturing experience have gone into developing a needle valve for the new millennium.

The Balon needle valve is the result of many design inputs directed at a total solution to needle valve problems, rather than at one or two isolated and limited variations of outdated concepts. This synergistic approach provides a total product that is greater than the sum of its parts.

Perennial problems which have plagued needle valve users - such as premature seat failure and consequent leakage, internal contamination and wear, bonnet and stem blow-out hazards, and generally abbreviated service life - have all been attacked in the design of the Balon needle valve.

Balon's reputation for quality and performance is carried through to this new design concept, and the result is a fresh new option for the valve user. This is no "me too" product. This is the ultimate refinement of the valve art.

Avanvec stem design

All stems are 316 stainless steel for almost universal corrosion resistance and much longer life. Note also that the stem and bonnet bearing area is larger than normally encountered. This assures more precise alignment, gives a "superb quality feel" of operation, and enhances sealability. The stem threads, located above the stem sealing area, are protected from contamination by the flow medium, again contributing to smoother operation and longer life. The thread area is lubricated at the factory, and the stem seal prevents washout of the lubricant, making for a permanently lubricated valve.

Stem and seat protection

The color coded plastic stem protector keeps external contamination out of the thread area. A thick cross sectional area also limits and cushions downward handle movement, thus helping to prevent over-tightening of the stem, which often leads to premature seat destruction.

-

Carbon Steel 6000

Carbon Steel

Threaded Body Construction

- 6,000 PSI

- Resilient Seated Needle Valve

- 6,000 PSI

-

Carbon Steel 10000

Carbon Steel

Threaded Body Construction

- 10,000 PSI

- Resilient Seated Needle Valve

- 10,000 PSI

-

Stainless Steel 6000

Stainless Steel

Threaded Body Construction

- 6,000 PSI

- Resilient Seated Needle Valve

- 6,000 PSI

-

Stainless Steel 10000

Stainless Steel

Threaded Body Construction

- 10,000 PSI

- Resilient Seated Needle Valve

- 10,000 PSI

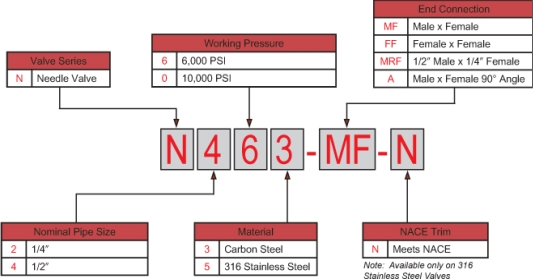

Needle Valve ID Key

The Benchmark for Needle Valves

-